When a vessel operator planning heavy cargo operations at Izmir Port—one of Turkey's busiest maritime hubs—required specialized lifting equipment for an urgent international shipment to São Paulo, Brazil, they faced a critical challenge: standard lifting gear couldn't safely handle their oversized cargo configuration. The operation demanded custom-engineered lifting beams capable of distributing 40 tonnes of load across multiple lift points while maintaining structural integrity throughout loading operations in Turkey and subsequent discharge operations halfway around the world in South America. With the vessel's arrival imminent and cargo operations scheduled within a tight commercial window, Seaway Ship Services was challenged to deliver a complete turnkey solution—from initial engineering through fabrication, testing, certification and delivery—in just 10 days.

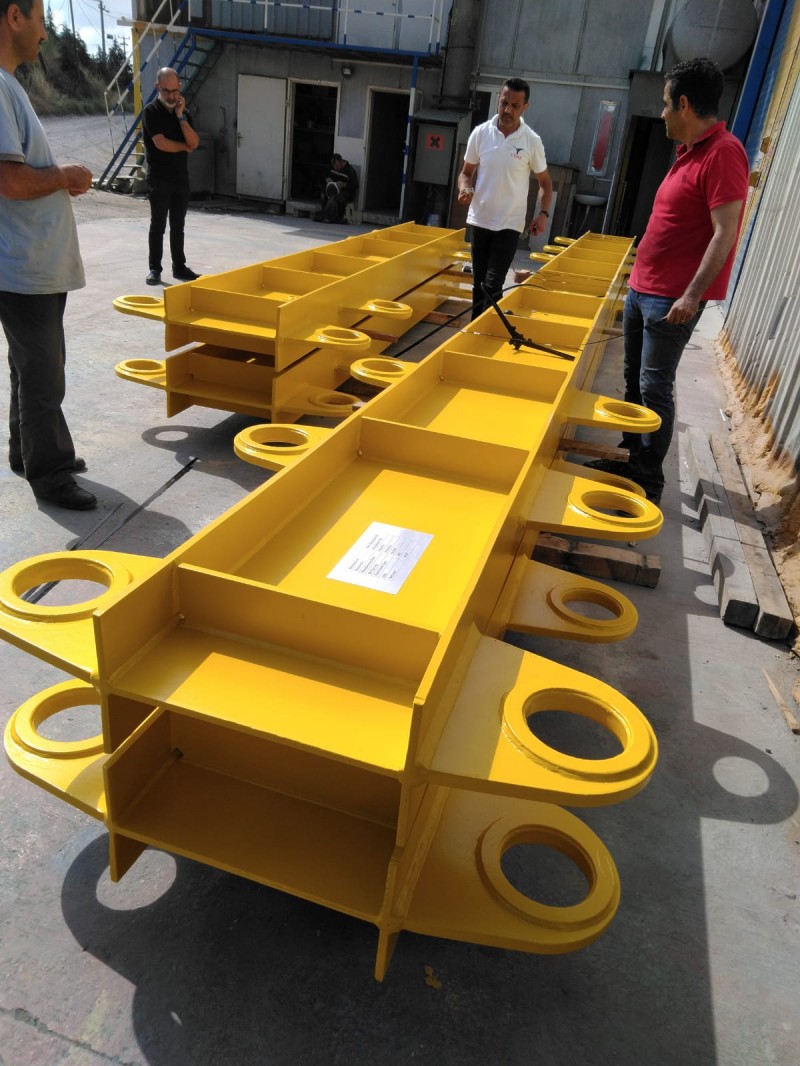

This project exemplified the convergence of precision engineering, rapid fabrication capabilities and rigorous quality assurance that defines Seaway's approach to critical marine equipment. Our engineering team began with comprehensive load analysis and structural calculations, developing lifting beam designs that would safely distribute the cargo's weight across multiple attachment points while accounting for dynamic loading factors during crane operations. The design incorporated reinforced box-section construction with internal stiffeners, precision-machined lifting eyes rated for individual loads and strategically positioned attachment points to ensure load balance. Every aspect of the design required validation through finite element analysis (FEA) to identify stress concentrations and verify safety factors.

The fabrication phase demanded meticulous attention to detail and quality at every stage. Our shipyard team executed precision steel cutting and forming operations, complex welding by certified marine welders following approved procedures and dimensional control throughout assembly to ensure the lifting beams would perform exactly as engineered. Following fabrication, each beam underwent comprehensive non-destructive testing including ultrasonic examination of critical welds and magnetic particle inspection for surface defects. The final validation came through certified load testing at 102% of safe working load (40.8 tonnes test load for 40-tonne SWL), witnessed by classification society surveyors who issued full certification for international use. The completed beams—finished in high-visibility safety yellow coating—were delivered to Izmir Port ready for immediate deployment, enabling successful cargo operations in both Turkey and Brazil while meeting all international maritime safety standards.